At B&B Sheet Metal, we specialize in crafting all types of wall flashings using a wide range of bendable materials. Whether you need a standard solution or a custom design, we have the expertise to get it done. In many cases, we can complete your order while you wait, ensuring fast and reliable service.

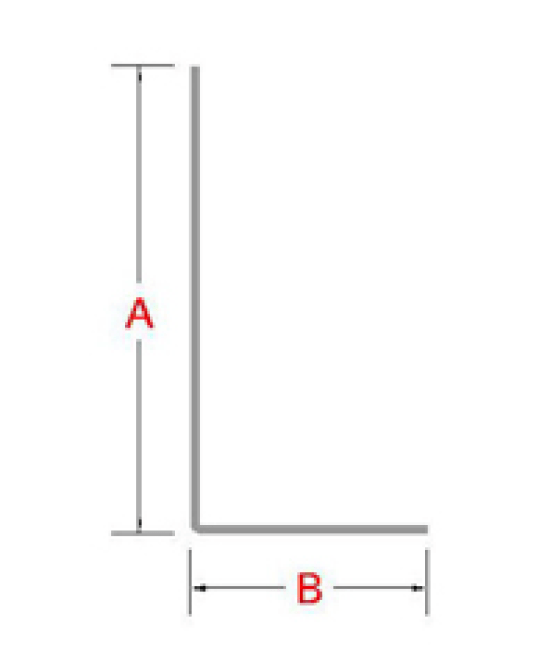

Base Flashings are the portion of a flashing attached to or resting on the deck to direct the flow of water onto the roof covering. A Base Flashing consist of piles of roof membrane material used to seal a roof at the vertical plane intersections, such as at a roof-wall and roof-curb junctures.

Share

Base Flashings are typically angles that are used for attaching roofing materials to as well as capping the top to ensure that the base of the roof is secured. It also allows for the expansion and contraction of the roof and wall. We recommend using a metal primer before installing the roofing materials to the base of the base flashings. This will allow the parts to stick and not break away over time. We offer any style base flashing available.

A Base Flashing is located at the joint between a roofing surface and an intersecting vertical surface, such as a wall or a parapet.

Base Flashings are the portion of a flashing attached to or resting on the deck to direct the flow of water onto the roof covering. A Base Flashing consist of piles of roof membrane material used to seal a roof at the vertical plane intersections, such as at a roof-wall and roof-curb junctures.

Share

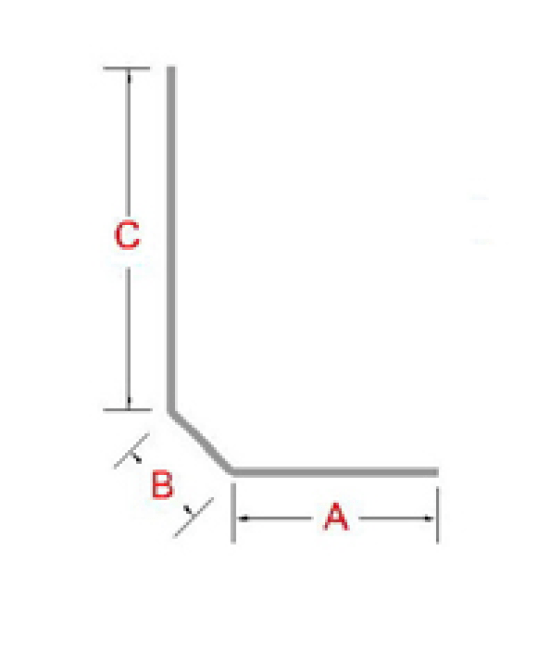

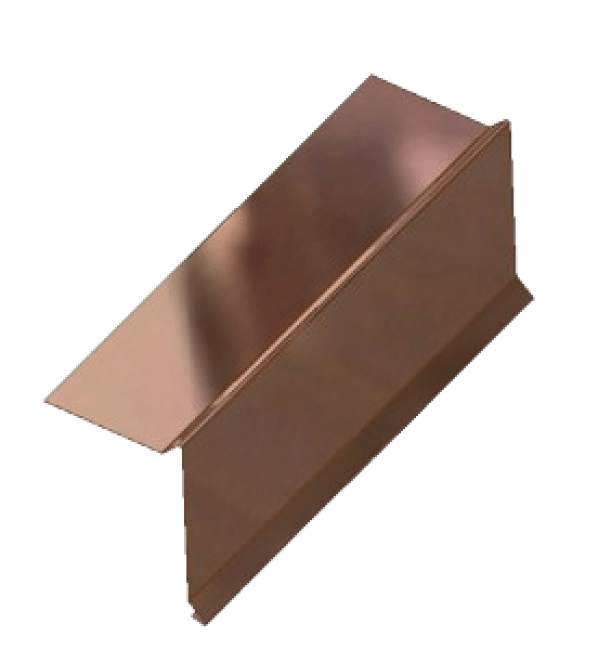

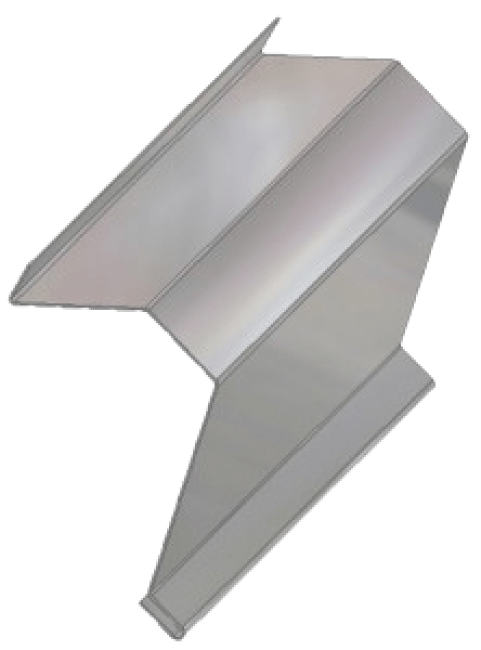

A Base Flashing B has a cant bent in the middle. This style keeps water away from the wall, which is one of the most vulnerable spots.

Base Flashing B is a great way to prevent leakage.

Base Flashings are the portion of a flashing attached to or resting on the deck to direct the flow of water onto the roof covering. A Base Flashing consist of piles of roof membrane material used to seal a roof at the vertical plane intersections, such as at a roof-wall and roof-curb junctures.

Share

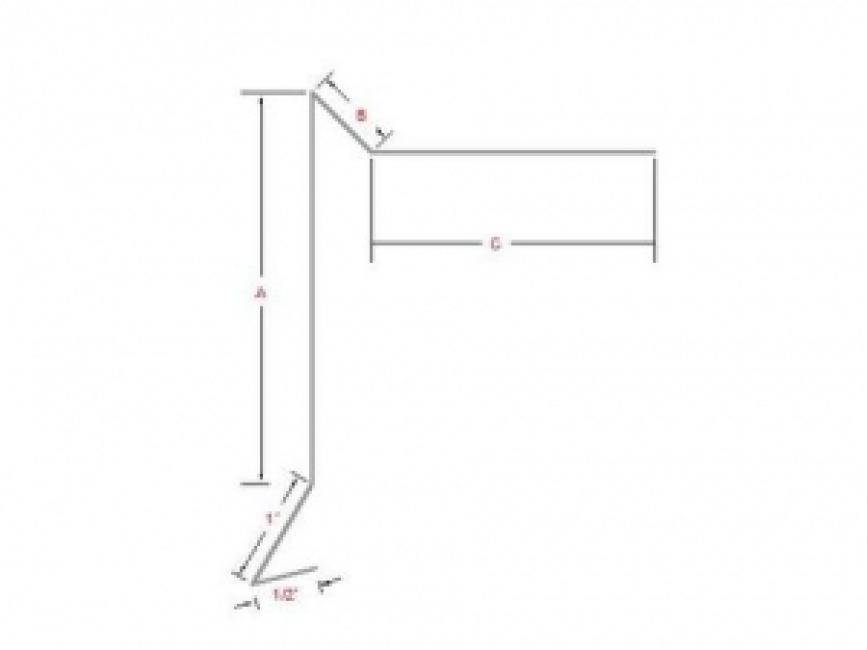

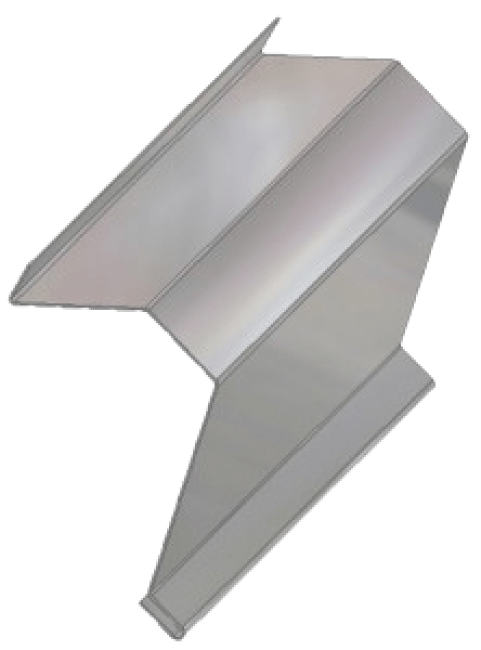

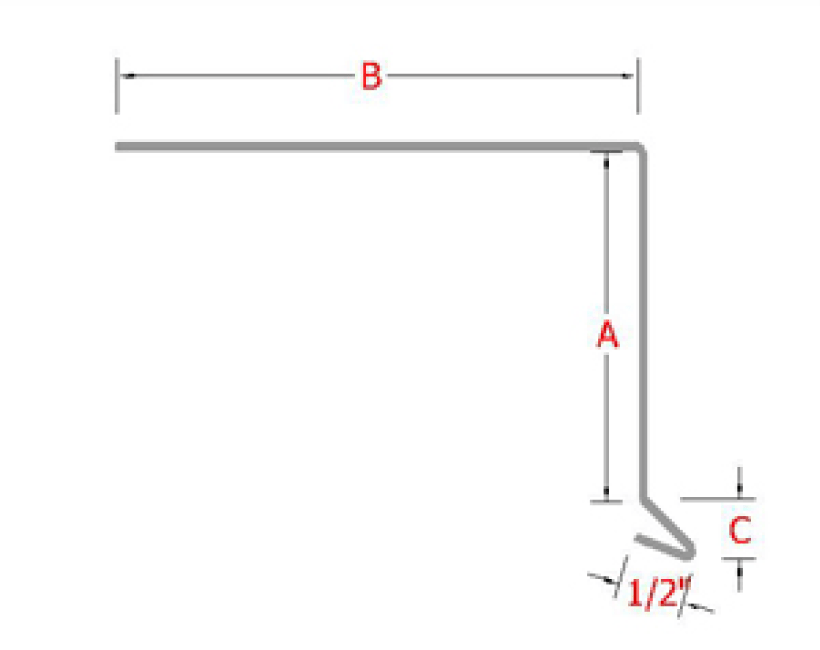

A Base Flashing C maintains a return bend on the bottom responsible for directing water to the gutter. This style is most commonly used on Spanish tile roofs.

A Base Flashing C is used to channel water to the gutter for consequent disposal.

Step Flashings are an application method used where a vertical surface intersects with a sloping roof plane. A Step Flashing can be located along a roof slope against a wall or chimney using succeeding courses of flashing material placed in conjunction with layers or courses of roofing materials. A Step Flashing generally appears in 4x4x8 inch segments.

Share

Custom Step Flashings can be customized to your impossible desires.

A Custom Step Flashing is a flashing along a roof slope against a wall or chimney using succeeding courses of flashing material placed in conjunction with layers or courses of roofing materials. Step Flashings are generally in 4 by 4 by 8 inch pieces.

Step Flashings are an application method used where a vertical surface intersects with a sloping roof plane. A Step Flashing can be located along a roof slope against a wall or chimney using succeeding courses of flashing material placed in conjunction with layers or courses of roofing materials. A Step Flashing generally appears in 4x4x8 inch segments.

Share

Custom Step Flashings can be customized to your impossible desires.

A Custom Step Flashing is a flashing along a roof slope against a wall or chimney using succeeding courses of flashing material placed in conjunction with layers or courses of roofing materials. Step Flashings are generally in 4 by 4 by 8 inch pieces.

Surface Mounted Counter Flashings rely on a bead of sealant at the top horizontal edge. Its sections overlap with ease for continuous counter flashing of wall terminated roofing. When using a surface-mounted termination, such as a Surface Mounted Counter Flashing helps to ensure that there is a consistent seal at the wall interface — the surface above the termination must be waterproof.

Share

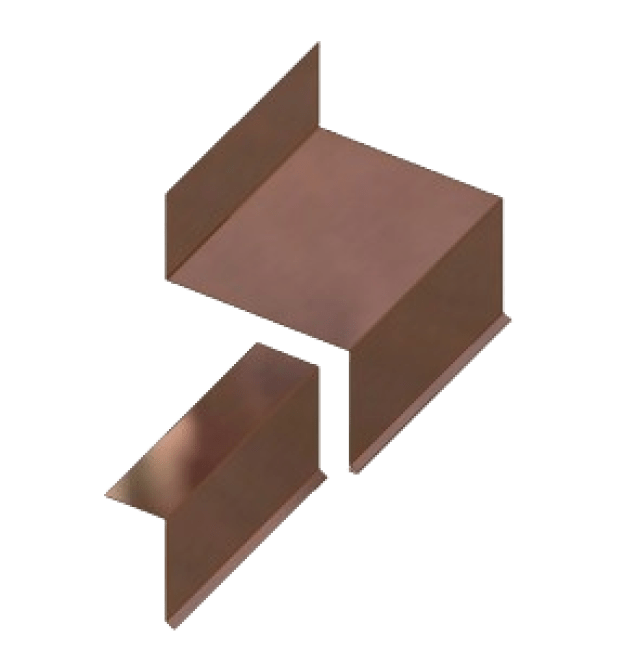

2 Piece Surface Mounted Counterflashing is made up of sections that easily overlap for continuous counter flashing of wall terminated roofing.

2 piece design provides a double weather resistant seal that is compatible and complements all flashing membranes. The pinnacle of waterproof protection!

Surface Mounted Counter Flashings rely on a bead of sealant at the top horizontal edge. Its sections overlap with ease for continuous counter flashing of wall terminated roofing. When using a surface-mounted termination, such as a Surface Mounted Counter Flashing helps to ensure that there is a consistent seal at the wall interface — the surface above the termination must be waterproof.

Share

Surface Mounted Counter Flashings are made to cover a base or step flashing. They make for a relatively simple installation — by fastening the surface mounted counter flashing to the outside of the wall using a concrete fastener.

A Surface Mounted Counterflashing or Reglet is a capping piece that is mounted to the surface of a wall and has a caulking flange to receive caulking. Since you don’t have to grind out a raggle, surface mounted reglets are usually installed much quicker than a regular reglets. They protect the base flashings. They have a beveled front edge to avoid back pitching and are pre-notched for inter-connectivity pieces.

Since surface mounted counterflashings rely primarily on sealant maintenance in order to protect against leakage, we recommend the integral style whenever possible. The integral style relies on watershedding ability and placement of the top edge of the metal within the wall assembly, which is more reliable in the absence of roof maintenance. Additionally, proper consideration should be given to the types of metal and fasteners specified, which affect the longevity of roof terminations. Proper fastener types with corrosion resistant coatings will slow corrosion rates compared with commodity grade zinc coated fasteners. Metal types and finishes also vary widely. A maintenance-free factory applied coating such as Kynar 500/Hylar 5000, or stainless steel, will generally prevent corrosion and finish deterioration, when compared to galvanized steel.

Gravel Stop Systems are specifically designed to prevent loose aggregate debris from washing off the roof. Additionally, they provide a continuous finished edge for the roofing. A Gravel Stop System is a proactive way to keep the maintenance life of your roof at an optimum. This system is synonmous with roof system longevity attributed to its unique and praiseworthy pesky-problem-removing power.

Share

The Continuous Cleat Metal Gravel Stop System are hooked onto the cleat and fastened through the nailing flange. Concealed splice plates are used for a neat water tight connection.

B&B Sheet Metal makes a Continuous cleat gravel stop system that is applied by first connecting the continuous cleat. B&B gravel stops can be made in Copper, LCC, Stainless Steal, Terne Coated Stainless Steel, Freedom Grey and Kynar. We also offer a Standard Style Gravel Stop System which requires no cleat and is appropriate for standard jobs.

Gravel Stop Systems are specifically designed to prevent loose aggregate debris from washing off the roof. Additionally, they provide a continuous finished edge for the roofing. A Gravel Stop System is a proactive way to keep the maintenance life of your roof at an optimum. This system is synonmous with roof system longevity attributed to its unique and praiseworthy pesky-problem-removing power.

Share

Standard Style Metal Gravel Stop System consists of a flanged metal strip used to prevent gravel or loose surfacing from washing off a roof and causing structural harm as well as potential physical injury to any passersby. This overhang helps to stop and collect any debris.

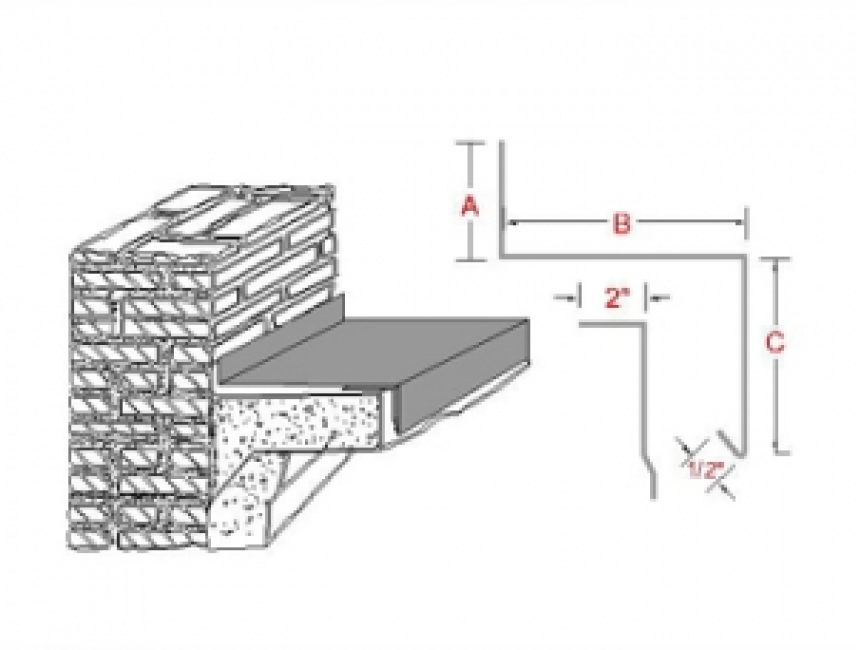

Ledge Flashings are eponymic for their essential function: covering a ledge. A Ledge Flashing is a great way to guard against an otherwise defenseless joint. They can also make basements safer and drier with waterproofing systems and basement products for lower level structures.

Share

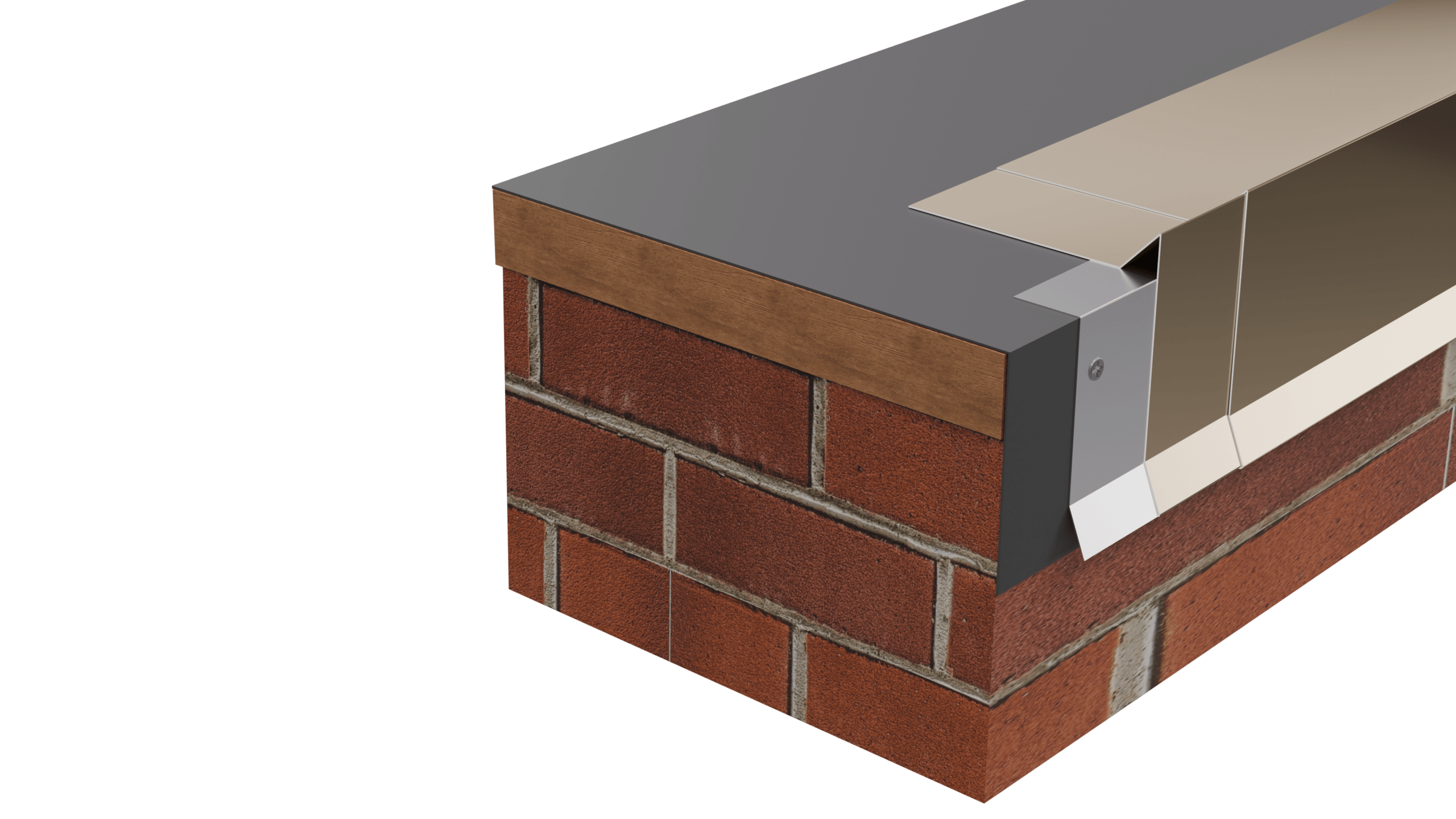

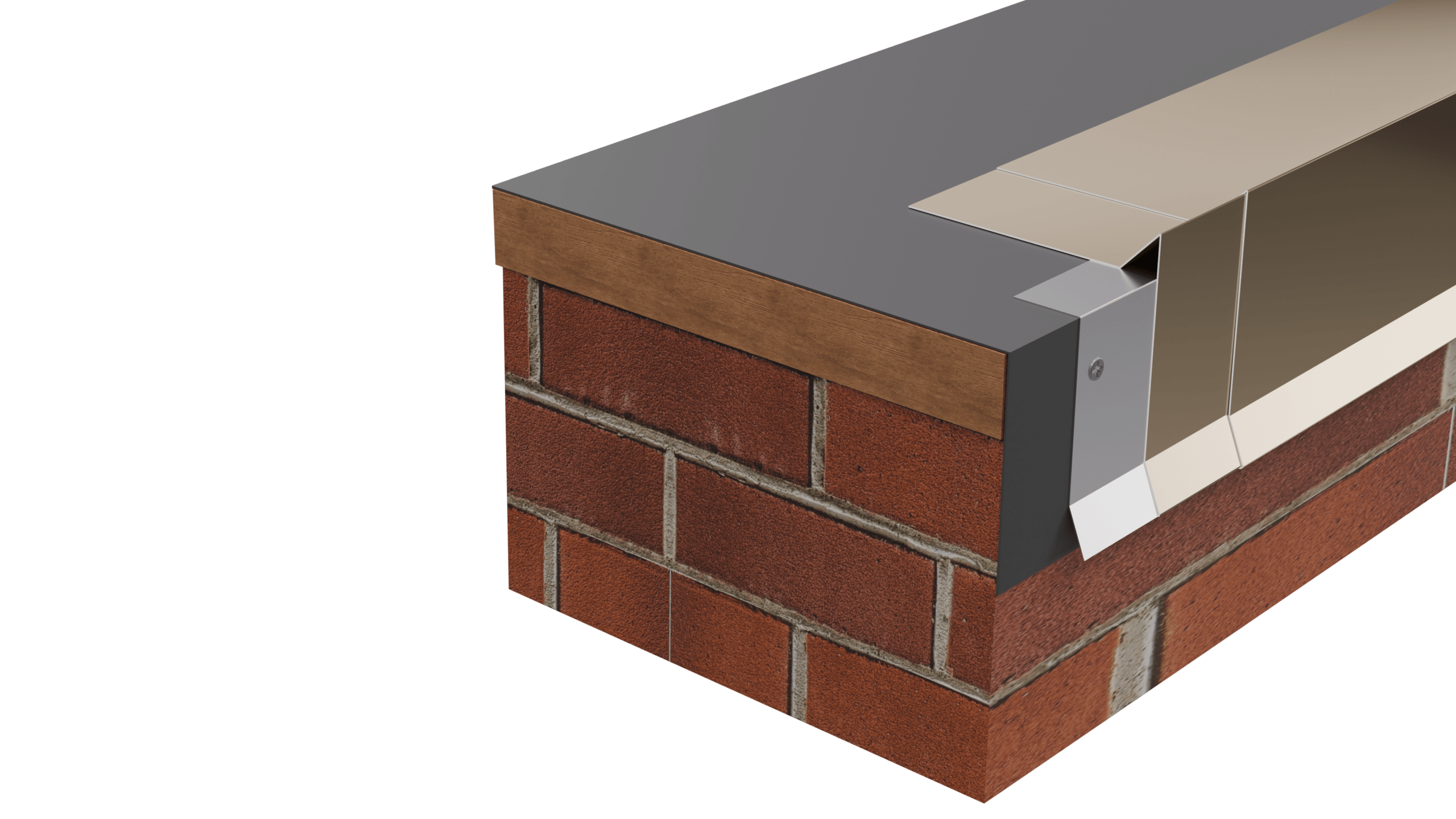

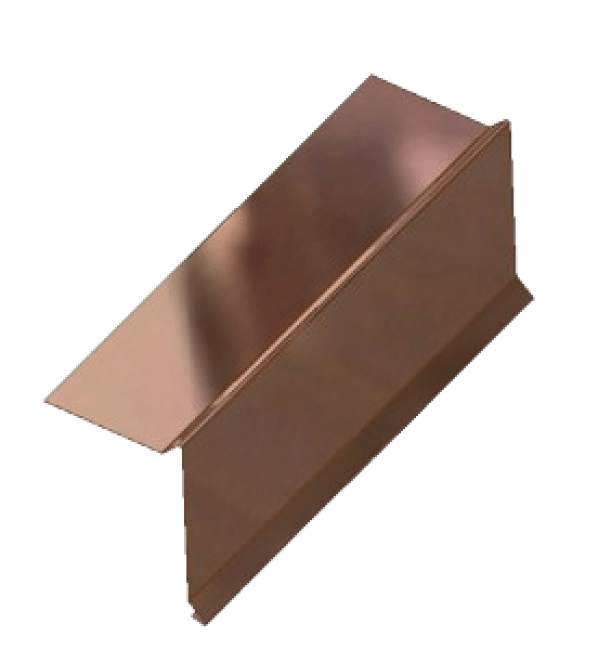

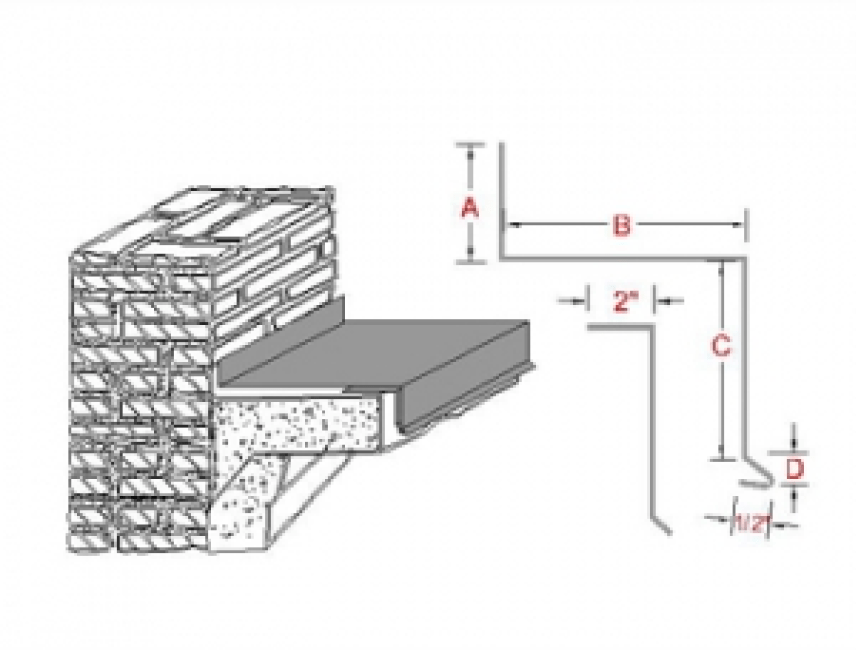

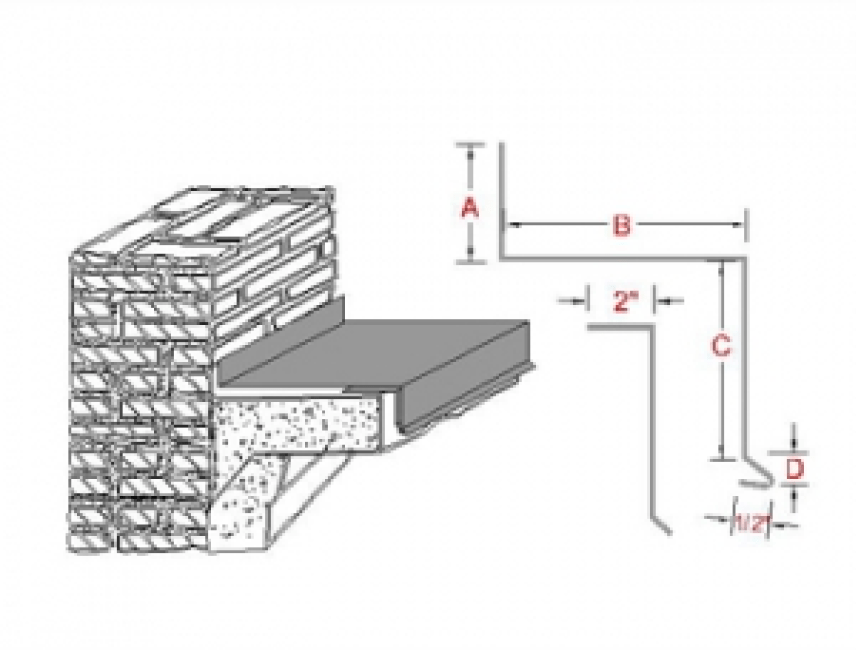

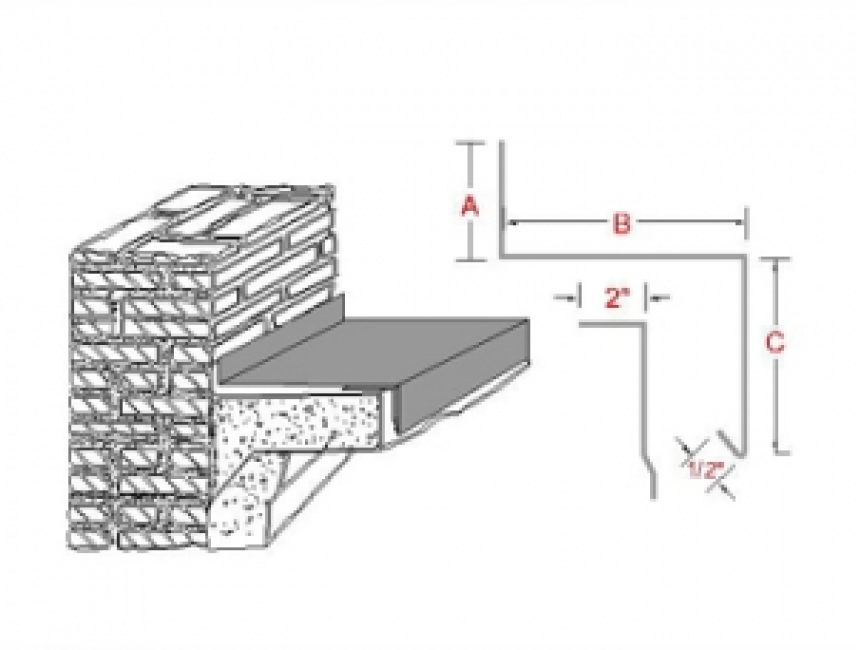

Ledge Flashings comprise a combination of a coping and a base flashing. They are used to cap the ledge that extends away from the wall. Additionally, they provide a back section to the wall creating a water tight seal.

A Ledge Flashing is a hybrid between copings and base flashings, capping the ledges that protrude from the wall.

Ledge Flashings are eponymic for their essential function: covering a ledge. A Ledge Flashing is a great way to guard against an otherwise defenseless joint. They can also make basements safer and drier with waterproofing systems and basement products for lower level structures.

Share

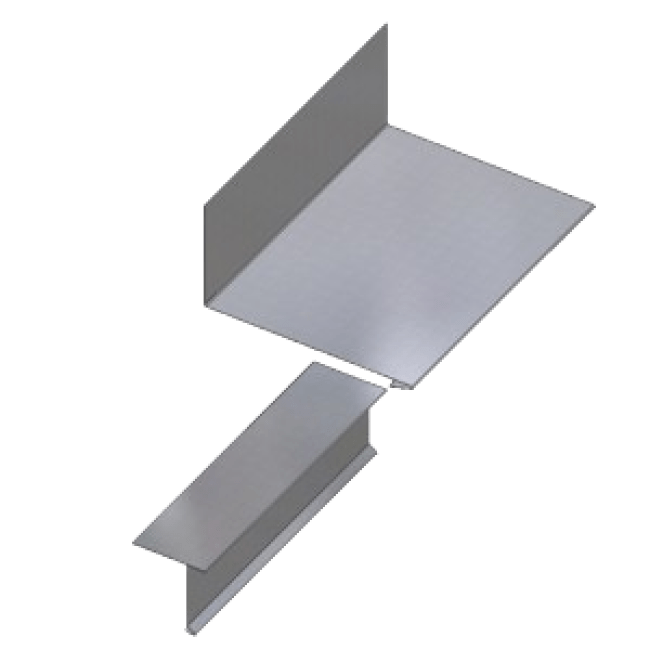

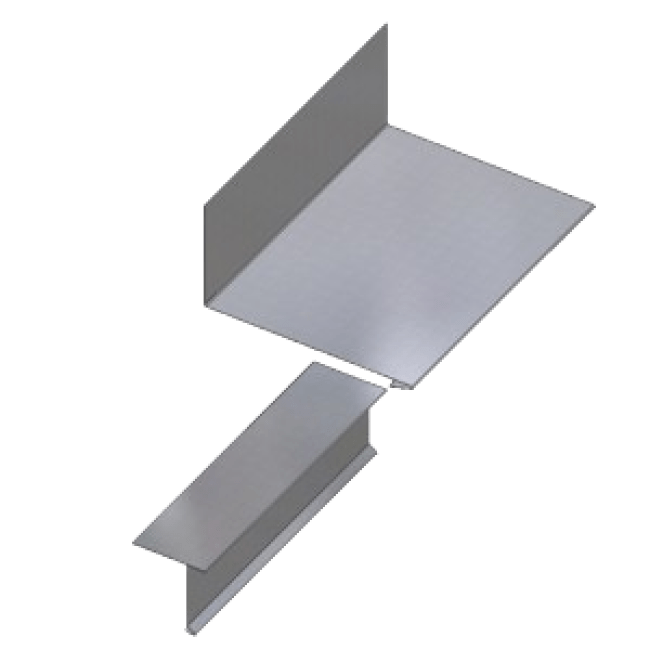

Ledge Flashing B does not have a drip kick; rather, it has a continuous cleat to facilitate easy (and fast) installation.

The Ledge Flashing B facilitates quick and simplified installation, with results that are a real crowd pleaser. The continuous cleat is actually quite neat, and at a price you can’t beat.

Ledge Flashings are eponymic for their essential function: covering a ledge. A Ledge Flashing is a great way to guard against an otherwise defenseless joint. They can also make basements safer and drier with waterproofing systems and basement products for lower level structures.

Share

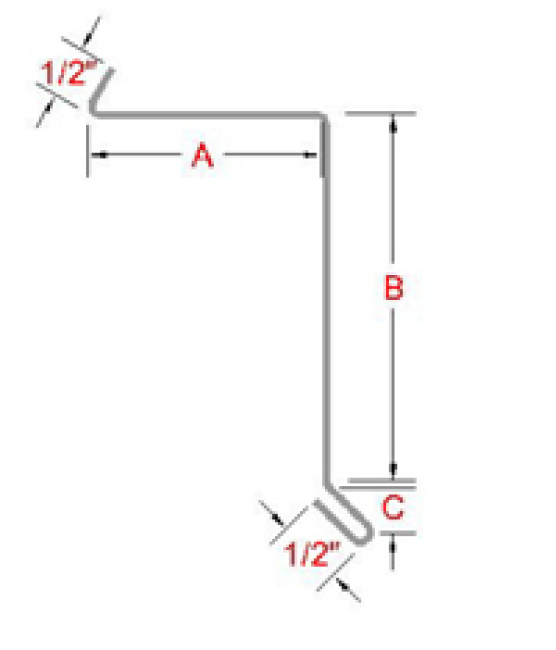

Ledge Flashing C comes with a cleat that extends 1 inch away from the ledge.

A Ledge Flashing C is an excellent way to bring sanity to the chaos created by the vulnerable ledge joint.

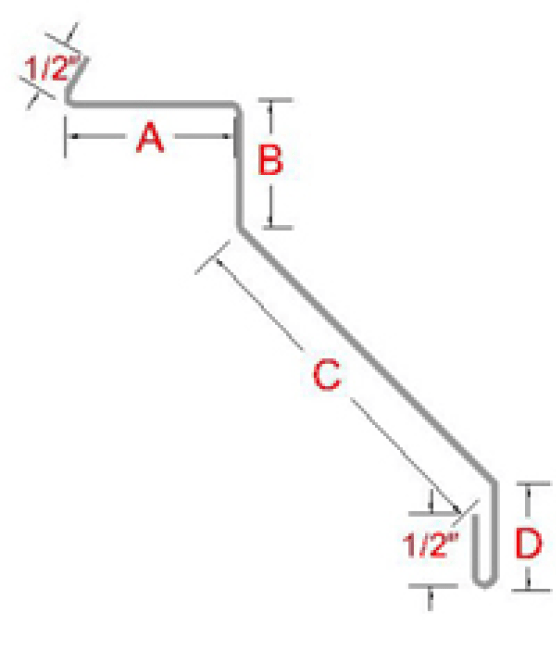

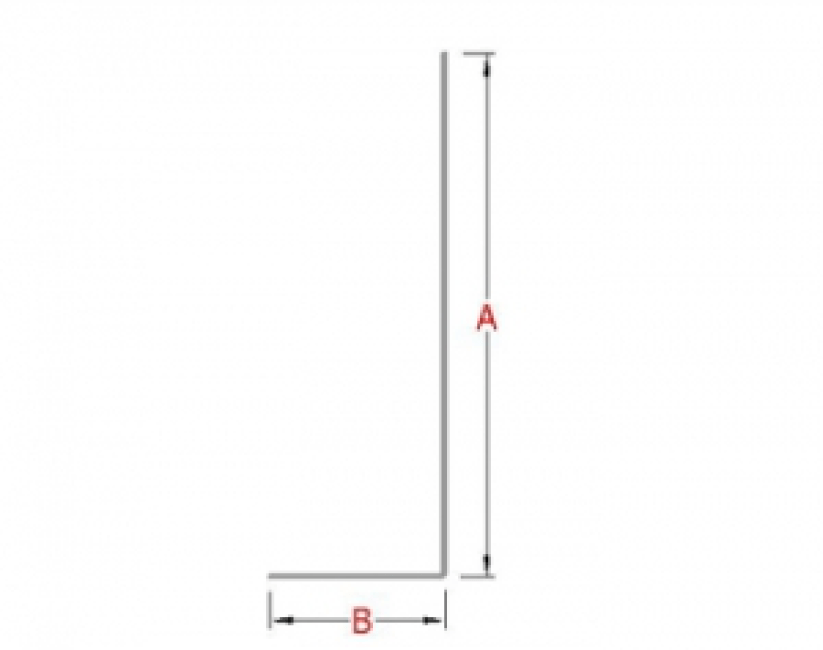

Reglet Counter Flashing A has a cut into brick and goes straight down, thus producing a flat strip along the entire wall. Easiest Installation of the all the counter flashings offered.

Share

Reglet Flashings are grinded into the reglet using a handheld grinder. Although this is a dusty and messy process, once it is complete, the flashing looks like a through wall flashing. This extra step is done solely to improve the appearance and does not offer any additional functional benefits.

A Reglet Flashing is a capping piece that is tucked into a joint and grinded into a mortar joint above the desired course of bricks. Although it is not a true through wall flashing, it only requires grinding the mortar joint as against taking out a course of bricks; thus it is an economical choice when appearance is the biggest concern.

Reglet Flashings are grinded into the reglet using a handheld grinder. Although this is a dusty and messy process, once it is complete, the flashing looks like a through wall flashing. This extra step is done solely to improve the appearance and does not offer any additional functional benefits. A Reglet Flashing is a capping piece that is tucked into a joint and grinded into a mortar joint above the desired course of bricks. Although it is not a true through wall flashing, it only requires grinding the mortar joint as against taking out a course of bricks; thus it is an economical choice when appearance is the biggest concern.

Share

Reglet Counter flashing B kicks out and then back in, creating a spring-like effect that enables the piece to hug the wall tighter.

The Reglet Counter flashing diverts water to the base flashing, which, in turn, diverts it to the composition flashing. The base flashing is designed to accommodate building movement.

Reglet Flashings are grinded into the reglet using a handheld grinder. Although this is a dusty and messy process, once it is complete, the flashing looks like a through wall flashing. This extra step is done solely to improve the appearance and does not offer any additional functional benefits. A Reglet Flashing is a capping piece that is tucked into a joint and grinded into a mortar joint above the desired course of bricks. Although it is not a true through wall flashing, it only requires grinding the mortar joint as against taking out a course of bricks; thus it is an economical choice when appearance is the biggest concern.

Share

Reglet Counter Flashing C has an outward kick that runs water away from the wall and then kicks back down: forming a spring-like effect.

The Reglet Counter flashing has a spring-kick in order to provide the most water-tight penetration.

Reglet Flashings are grinded into the reglet using a handheld grinder. Although this is a dusty and messy process, once it is complete, the flashing looks like a through wall flashing. This extra step is done solely to improve the appearance and does not offer any additional functional benefits. A Reglet Flashing is a capping piece that is tucked into a joint and grinded into a mortar joint above the desired course of bricks. Although it is not a true through wall flashing, it only requires grinding the mortar joint as against taking out a course of bricks; thus it is an economical choice when appearance is the biggest concern.

Share

Reglet Counter Flashing D expands away from the wall for extra coverage and joint protection.

This joint protection protects the critical juncture effectively.

Reglet Flashings are grinded into the reglet using a handheld grinder. Although this is a dusty and messy process, once it is complete, the flashing looks like a through wall flashing. This extra step is done solely to improve the appearance and does not offer any additional functional benefits. A Reglet Flashing is a capping piece that is tucked into a joint and grinded into a mortar joint above the desired course of bricks. Although it is not a true through wall flashing, it only requires grinding the mortar joint as against taking out a course of bricks; thus it is an economical choice when appearance is the biggest concern.

Share

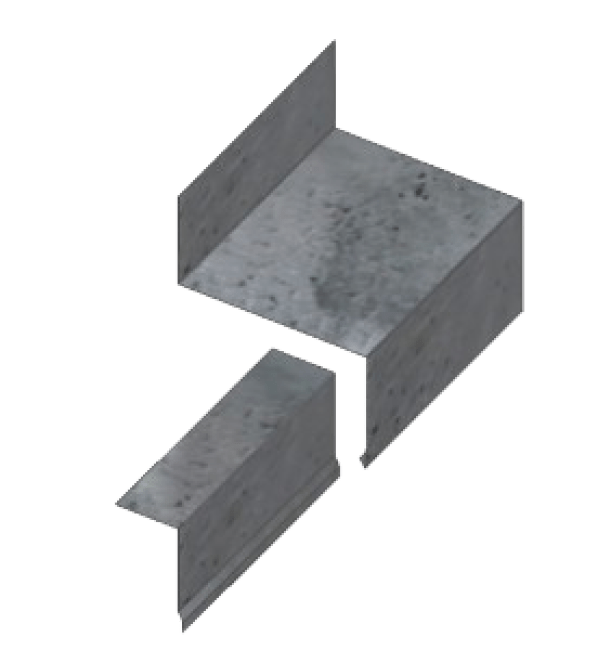

2 Piece Reglet Counter Flashings are designed for the 2 pieces of the system to be installed at different stages of the installation, allowing for flexibility.

When installing 2 piece counter flashings, you can be assured that the ends are designed to slide into each other, thereby providing a clean connection. We also make pre-fabricated miters to allow for a smoother installation.

Metal Fascia Systems are perimeter guards that work to keep the hemline and overall structure impervious to water penetration. This system is low maintenance and is very pliant and easy to work with.

Share

The Metal Fascia System is a sheet metal Dam to prevent water seepage. This style system easily integrates with seemingly any gutter or soffit system and is both durable and hard-working.

Metal Drip Edge Systems are strips extending beyond other parts of the roof to direct rainwater off of the roof. Our Metal Drip Edge Systems can be fabricated in a multitude of different finishes.

Share

A Drip Edge has an outward projecting lower edge. This edge controls the flow of water and protects other building components. A Drip Edge can also be used to break contact of objects such as a roof and a wall.